This is an old revision of the document!

Table of Contents

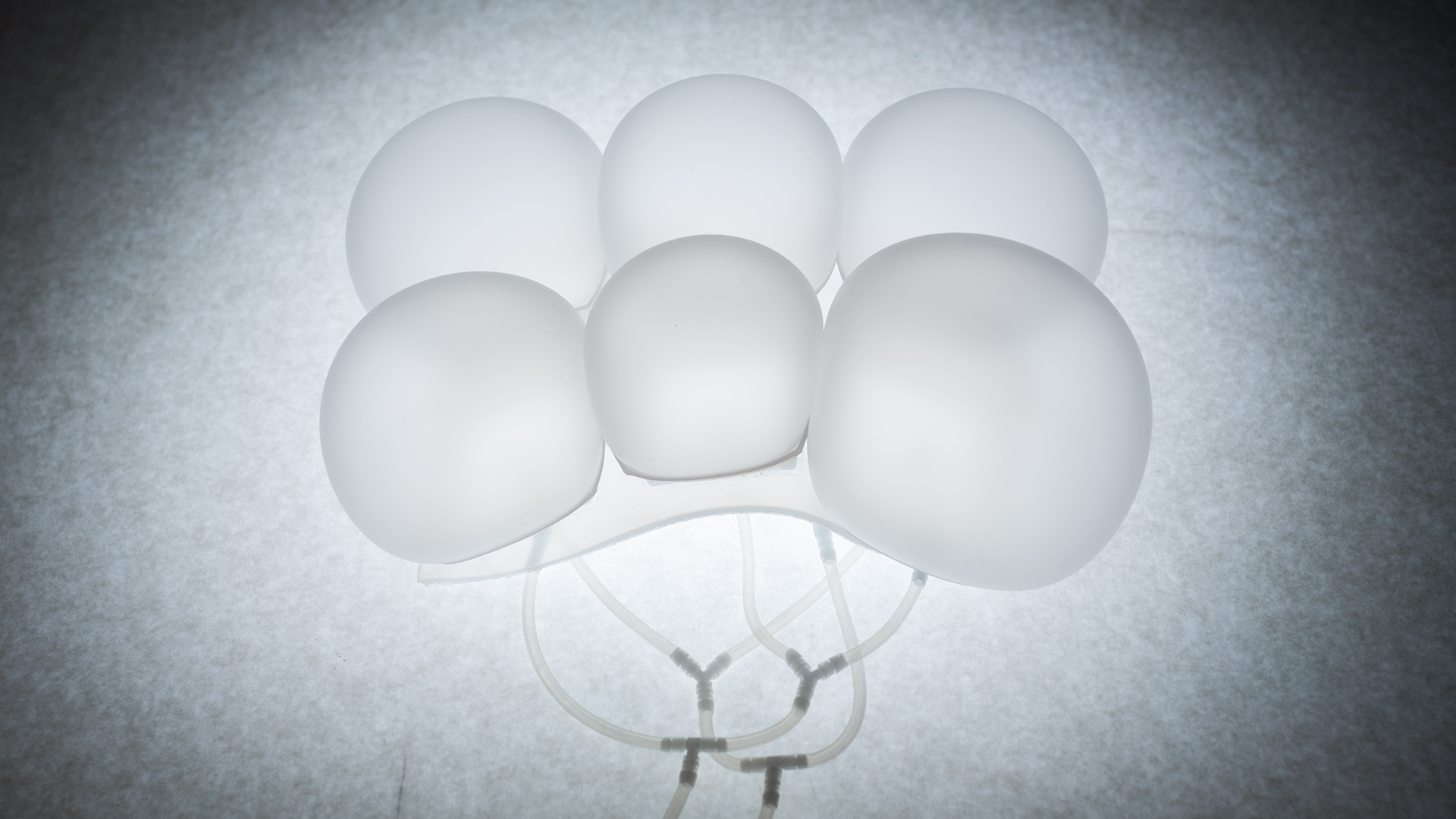

Pneumatic surface CNC

Based on the Fast Pneunet architecture.

Fabrication

Cavity: Polyurethane foam, acrylic glass and screws. CNC milled and assembled.

Bottom layer: acrylic glass and double sided tape.

Mold files

Casting

The Mould has an inlet hole for a syringe and an air outlet on the opposite site. The bottom and top part of the upper cavities mould are made or transparent acrylic glass to observe any air traps while injecting the silicone. The mould has to be held in a way that the silicone inlet is the lowest point and can be filled up from bottom to top. That way the air will be pushed up and out through the air outlet. When the mould is casted it needs to be stored in a way that both wholes point upwards in order to keep the silicone inside the mould while drying. After drying the mould is being released by the aids of two screws located on the top part part of the mould. The screws need to be turned slowly to prevent the silicone from ripping and to leave enough time for the silicone to deform. If needed a release agent can be added to the mould before casting.

Oven times

Ecoflex 30 about 20 min at 65°C

Basic shape

Air inlet

The Bottom plate has holes in order to place the tubing before casting the bottom surface.