−Table of Contents

General recipe for preparation of soft actuators

The following steps describe our methodology for preparing soft actuators.

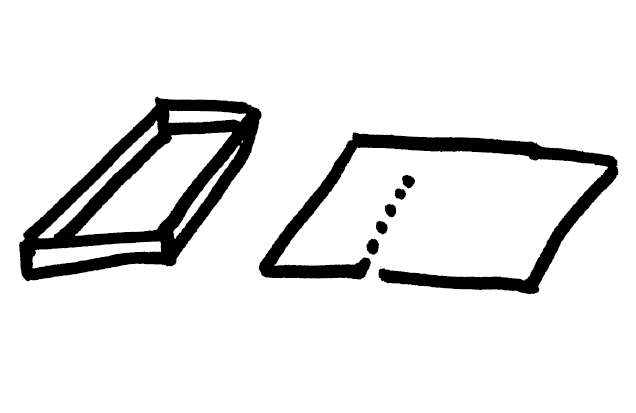

1. Choose your mold and figure out required silicone quantities

- Refer to the molds page for a list of known molds and quantities.

- Check if your mold is a Fast Pneunet or Slow Pneunet to figure out which silicone is supports.

- Leave at least 20gr for gluing.

- Get both body and base layers ready for pouring before you start mixing.

2. Apply coating to the molds

Coating the molds in Vaseline would later help removing the cured silicone from the mold.

3. Prepare any extra strain limiting materials

The base layer requires strain limiting materials. Choose the ones you will use and prepare them for placing over the uncured base silicone.

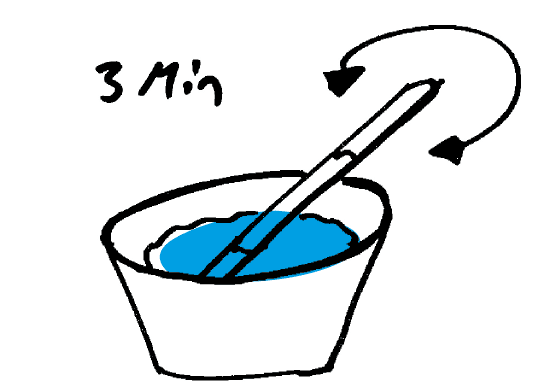

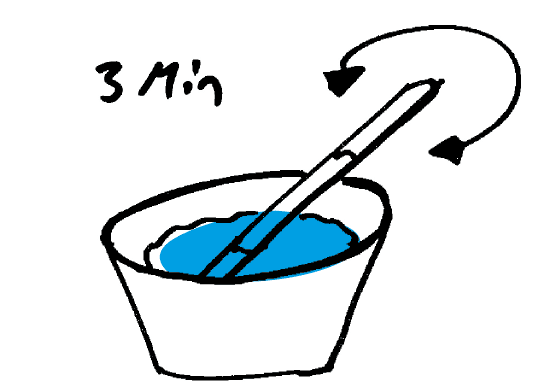

4. Mix the silicone

Refer to the silicones page to figure out the ratio working time of your silicone. If you don't have a centrifugal mixer, use wooden mixing sticks. Mix thoroughly for 3 minutes. Weak mixing may result in curing failure.

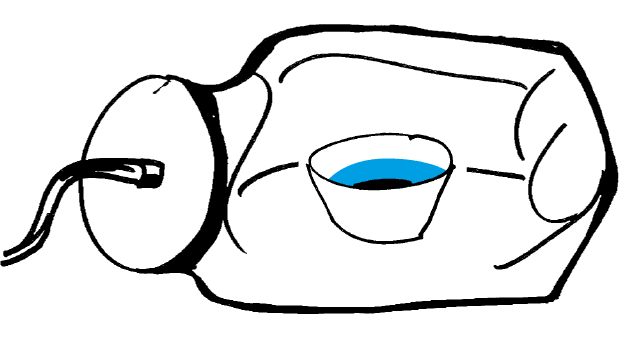

5. Place the mixed silicone cup in the vacuum chamber

5 minuets should be enough to get rid of initial bubbles.

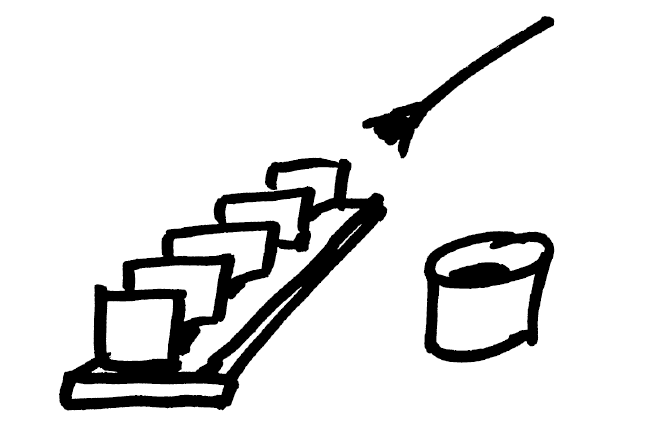

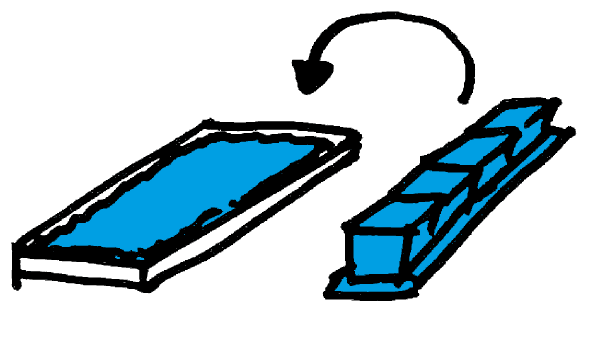

6. Pour the silicone into the molds

Pour gently and slowly. Allow the silicone to spread evenly and then pour more layers. For the base layer, pour only half of the silicone, as you will later add the strain limiting layer.

7. Place the molds in the vacuum chamber

After 5 minutes lots of bubbles will rise to the surface. Pop them out with a pipette tip or other plastic instrument.

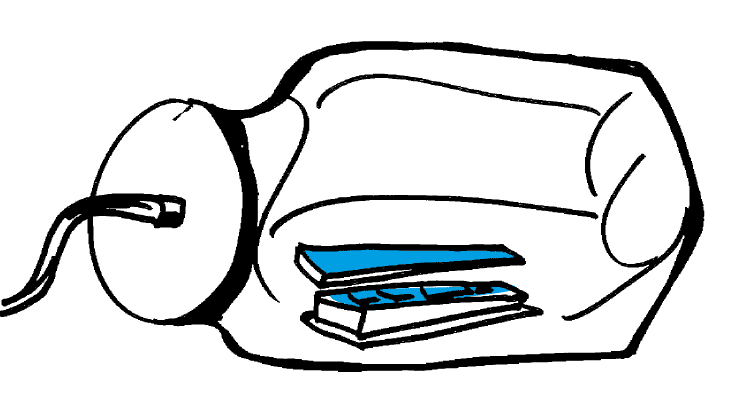

8. Place strain limiting material on the base layer

Refer to the strain limiting page for more info.

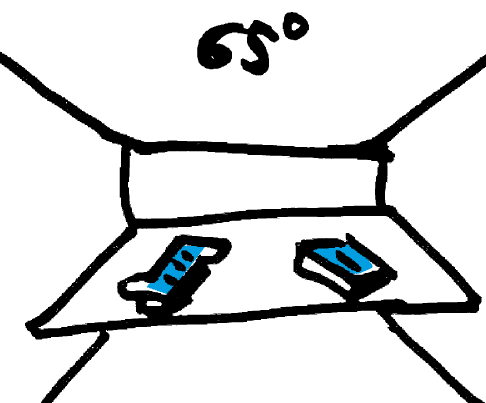

9. Place the molds in the oven at 65C

Refer to the page of your silicone and mold for the approximate time needed, Once the time is up, perform 2 checks:

- Check that the silicone is hardened and doesn’t stick to your glove or feel gooey - If it's not ready, put it back in the oven for more time.

- Check that the fill height didn’t drop more than 2mm - If it did, fill in extra silicone (Make a new cup, don't use an old one) and put back in he oven.

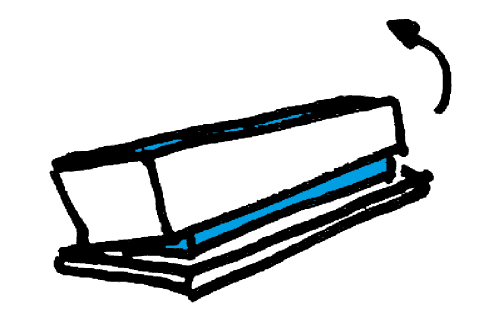

10. Remove the cured silicone from the molds

Each mold may have different methods for removing. The silicone is quite strong so it's OK to use a flathead screwdiver. We have also used a metal knitting needle to cut through the seams of the mold.

Notice that if you overfilled your mold, you may have silicone attached above the edges of the mold. Use a utility knife to cut the excess attachment.

11. Make new silicone for the base layer + gluing

Do not reuse old silicone as it may have already been cured.

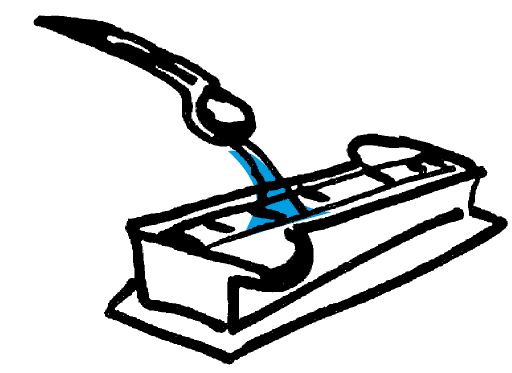

12. Glue the body layer to the base layer

- First put the base silicone back into its mold.

- Fill up new silicone all the way up to the base mold.

Refer to the soft robotics toolkit guide:

Place the top piece of the actuator on the base so that it settles into the uncured Silicone, and press down gently. If you press too hard, the central channel of the actuator may become blocked. Make sure to press down around the edges as well to ensure a good seal.

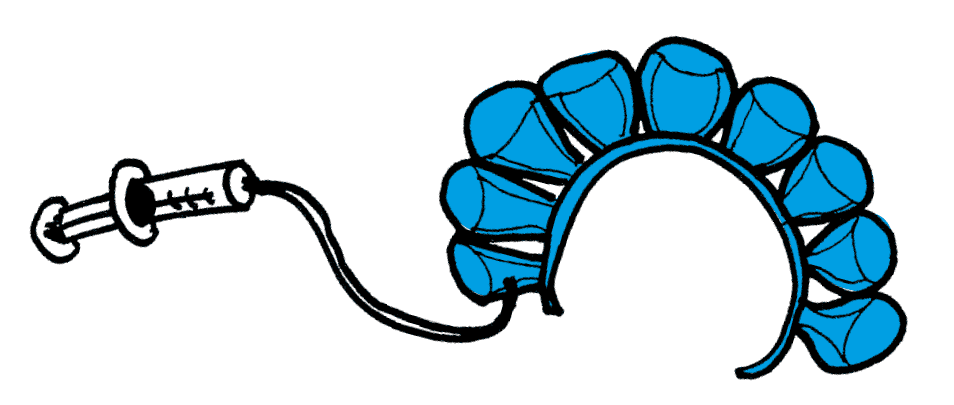

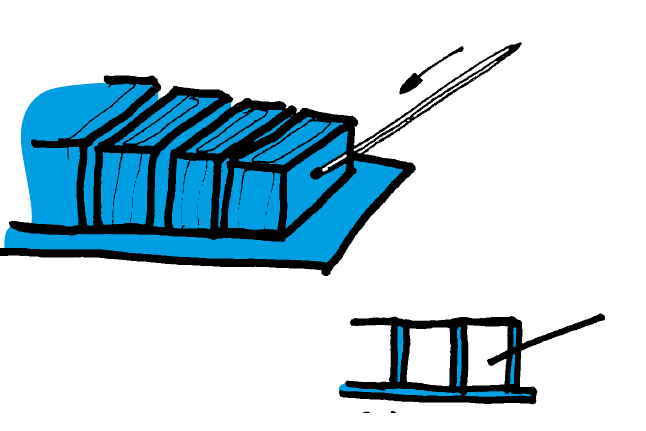

13. Pierce a hole in the actuator and insert the tube

Use the metal knitting needle to pierce the hole and gently attach the tube. Refer to the page of your mold for specific instructions on where and how to pierce the hole.

14. Gently test inflation with a syringe

Do not inflate too much! - If the inflation works properly, let the actuator rest and cure until the next day. Two main issues may be revealed:

- The air channel is blocked - If the actuator inflates only half way without any air running out, the air channel is blocked. use the knitting needle to gently pierce through the air channel until the block is removed.

- There is a hole - If air is running out of the actuator, immerse it in water while inflating to figure out where there is a hole. Use more silicone or silicone glue to patch the hole and try again.